Colleagues in welding operations must do a good job of personal protection and safety during welding operations. This is a very important thing.

During the welding process, the more common hazards are: arc radiation, toxic gases and smoke, high temperature burns, strong noise, etc. Analyzing the harmful factors, the safety protection experts made the introduction of welding protection products one by one in the order of personal protection equipment from top to bottom:

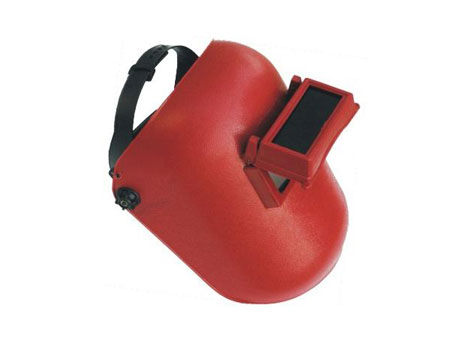

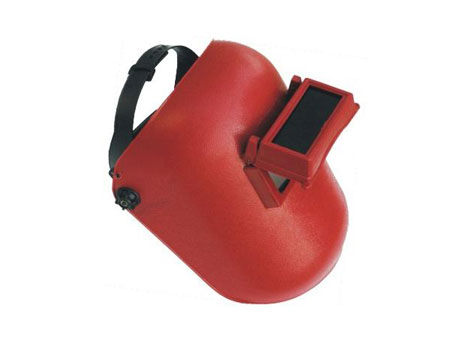

1. Eye and face protection: mainly arc radiation (welding radiation mainly includes ultraviolet, infrared and visible light) protection. Protective products include welding protective goggles and automatic darkening welding masks.

2. Respiratory protection: mainly for the protection of toxic gases and smoke. Toxic gases are mainly carbon monoxide, nitrogen oxide, hydrogen fluoride, ozone, etc.; toxic fumes include iron oxide, manganese oxide, silicon dioxide and fluoride, etc., and the more toxic manganese is poisoned. Protective products include welding masks, gas masks, long-tube respirators, electric air supply respirators, etc.

3. Hand protection: mainly for protection against high temperature burns. It is recommended to wear welding gloves, high temperature gloves, etc.

4. Body protection: mainly high temperature burns and arc damage. Protective products include welding protective clothing, welding aprons, etc.

5. Hearing protection: The main noise generated by welding includes plasma cutting and plasma spraying. You can use anti-noise earplugs and anti-noise earmuffs for protection.

6. Foot protection: high temperature particles such as sparks during welding are damaged. Protective products include safety shoes.

In short, it is necessary to improve their self-prevention awareness during welding operations and reduce the incidence of occupational diseases. At the same time, it is necessary to strengthen the monitoring of dust and poison hazards in electric welding workplaces and the physical examination of electric welders to find and solve problems in time. The body is the capital of work, and relevant protection should be done in normal work.

There are many pollution factors in the welding environment. In addition to the provision of personal welding protective equipment, a comprehensive improvement and management of pollution sources and transmission channels is also required. Enterprises need to develop and improve management and monitoring mechanisms based on their actual production needs and production characteristics, so as to protect the safety of workers in a real sense.

The information is provided by welding mask manufacturers.