Are you excited about learning to weld but unsure of what kind of tools you need? Whether you’re enrolled in a welding training program at a trade school or are just starting to dabble at home, having the right equipment can be important to producing clean, strong welds.

As one of the larger purchases you could make, you may have a lot of questions about welding machines:

What is the best welder for beginners?

Which welders are the least expensive?

What welder produces the most precise work?

Find answers to these questions and more below.

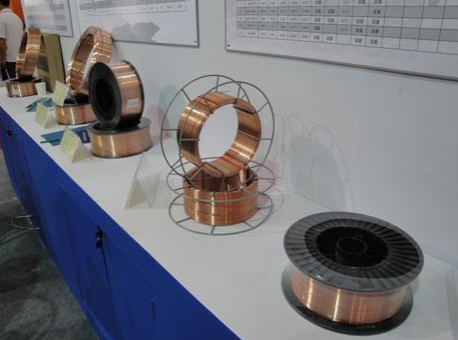

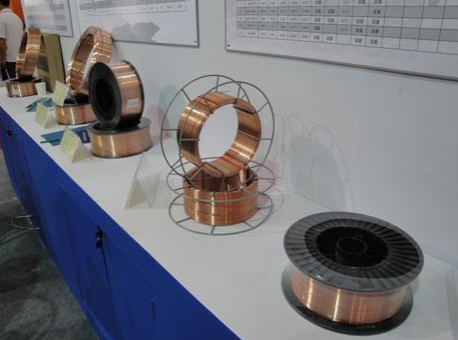

GB ER50-3 AWS ER70S-3

4 Considerations for Choosing a Welder

Fortunately, with so many types of welders to choose from, it’s possible to find one that suits your experience level, welding school, or project requirements and budget. One of the first things you may notice is how many options there are on the market for welding machines. Keep it simple. Focus on the basic equipment you need for welding classes or to start your first project.

When comparing welders, consider the following factors:

Your skill level

Type of welding process

Welding project or application

Budget1

3 Steps to Choosing Your First Welder

Buying your first welder can be a big decision. Let’s see how putting the considerations above into practice can help you with it. Keep in mind that it may take more steps—or fewer—for you to select the right machine for your needs.

Step 1: Match Your Skills to a Welding Process

MIG, Stick, and TIG are the most common welding processes, and each one requires a different type of machine setup.

Deciding which process you plan on learning first can help you determine the type of welder you need.

MIG Welding Machine

MIG Welding (Beginner)

MIG welders are among the best type for beginners, as they’re designed with a wire welding electrode on a spool that is fed at a pre-selected speed through a welding gun. As a semi-automatic or automatic process, gas metal arc welding (GMAW or MIG), is the easiest to learn.

MIG Welding Benefits

Simple to learn

High welding speeds

Cleaner welds

Stick Welding (Intermediate)

Compared to other welding processes, it may take longer to get the hang of shielded metal arc welding, or stick welding.

The name of this process can give you a clue as to what it entails: a flux-covered metal electrode is used to carry the electric current from the machine to the metal workpiece. As it burns, the flux emits a gas to shield the weld pool, which later settles to form a protective slag over the work. Meanwhile, the metal electrode melts into the joint, strengthening it.

Stick Welding Benefits

Works on a range of metals

Indoor and outdoor use in wind

Effective on rusty or painted materials

TIG Welding (Advanced)

Gas tungsten arc (TIG) welding requires advanced welding skills. One reason for this is that TIG welding is a manual process in which you hold the torch with one hand and feed the metal filler rod into the weld puddle with the other.

TIG Welding Benefits

Precision welds

Foot control to adjust heat input

Higher-quality, better-looking weld beads

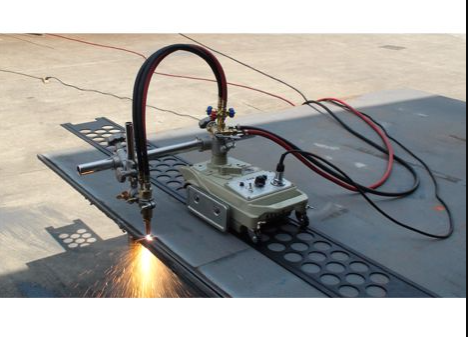

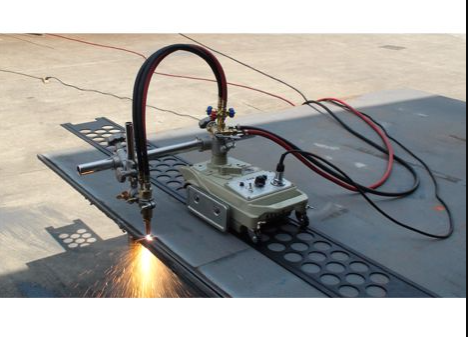

Gas Cutting Machine

Step 2: Align Welding Process with Project

In addition to skill level, you’ll also want to think about what types of projects you’ll be working on. Each welding process (and its specific welder) has unique applications.

MIG Welding

Automotive and trailer repair

Lawn and garden equipment repair

General fabrication and repair

Metal fabrication

Art and sculpting

Stick Welding

Farm and ranch equipment repair

Construction (structural welding)

Assembly of temporary structures

Jewelry making

TIG Welding

Automotive assembly.

Shipbuilding

Aircraft welding

NASA welding

Step 3: Determine which Welder Fits with Your Budget

Once you’ve figured out which type of machine you need, it’s time to shop around for the model that best fits your budget.

Be sure to factor in the costs of all the other welding equipment you’ll need when putting together a budget, such as the costs of the welding helmet, jacket, welding gloves, and other essentials.

Up Next: Choose a Welding Helmet

Any welder will tell you how important wearing a welding helmet is to keep you safe in the classroom or on the job site.

After you’ve selected a welder, the next step can be choosing a welding helmet.

It is our great honor to satisfy your requirements for welding products. Any requirement from you will be maximized by us. Let us help you find the best MIG welding machine for your project. When you contact us, please provide your detailed requirements. That will help us give you a valid quotation.