Welding is a complex and skilled trade, and understanding the terminology associated with it is crucial for effective communication and proficiency in the field. If you're looking to expand your knowledge of welding terminology, here are more common terms that you should be familiar with:

1. Backing Strip

A backing strip is a piece of material placed on the opposite side of the weld joint from the side where welding is taking place. It helps support the molten weld metal, preventing it from falling through the joint and ensuring proper penetration.

2. Crater

A crater refers to the depression or cavity at the end of a weld bead. It is essential to properly fill and finish the crater to prevent cracking and ensure the overall integrity of the weld.

3. Electrode

The electrode is the welding rod or wire used to carry the electric current necessary for creating the arc. It melts during the welding process, contributing to the formation of the weld bead.

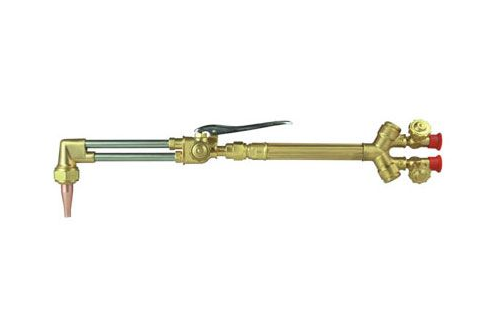

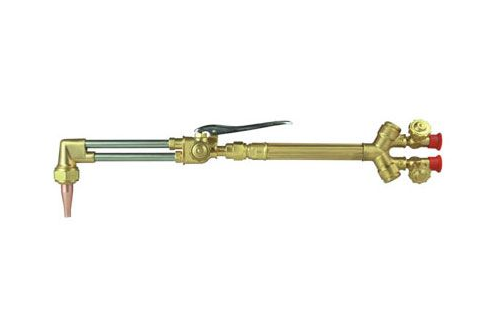

Welding Torch

4. Fusion

Fusion in welding refers to the melting and mixing of base metal and filler material to create a solid joint. Achieving proper fusion is essential for a strong and reliable weld.

5. Porosity

Porosity is the presence of small cavities or voids in the weld metal caused by gas entrapment. It can weaken the weld and compromise its integrity. Proper welding techniques and shielding gases help minimize porosity.

6. Tack Weld

A tack weld is a temporary weld used to hold parts in place before the final welding is done. It ensures proper alignment and prevents distortion during the welding process.

7. Undercut

Undercut is a groove or depression along the toe of the weld or base metal, typically caused by improper welding techniques. It can lead to stress concentration and reduced strength in the weld, making it essential to address during the welding process.

Welding Positioner

8. Welding Position

Welding position refers to the orientation of the weld joint relative to the welder. Common welding positions include flat, horizontal, vertical, and overhead. Proper technique varies depending on the welding position.

Questions and Answers

Q: What is the purpose of a backing strip in welding?

A: A backing strip provides support to the molten weld metal, preventing it from falling through the joint and ensuring proper penetration and fusion on the opposite side of the weld.

Q: How can porosity in welding be minimized?

A: Minimizing porosity involves using proper welding techniques, ensuring a clean workpiece, and using appropriate shielding gases to prevent gas entrapment in the weld metal.

Q: When is tack welding commonly used?

A: Tack welding is commonly used to temporarily hold parts in place before the final welding is done. It ensures proper alignment and prevents distortion during the welding process.

By familiarizing yourself with these additional welding terms, you can enhance your understanding of the welding process and contribute to the successful execution of welding projects. Whether you are a novice or an experienced welder, having a comprehensive knowledge of welding terminology is essential for professional growth and proficiency.