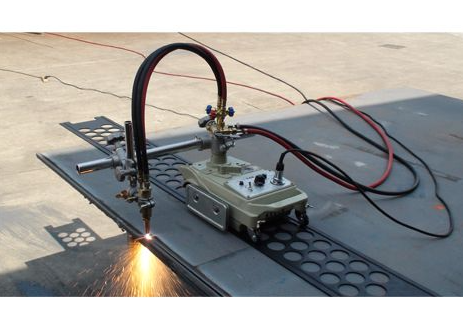

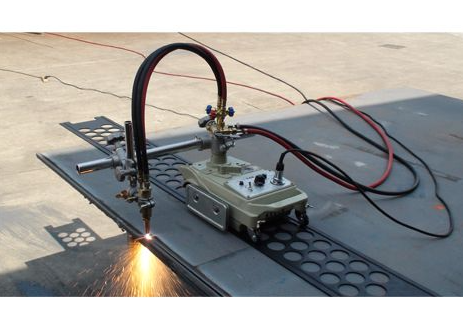

Gas cutting machines are versatile tools used in various industries for cutting metal sheets, plates, and other materials with precision and efficiency. Whether used for industrial fabrication, construction, or automotive applications, understanding the key features, operating principles, safety considerations, and applications of gas cutting machines is essential for optimal performance and safety. Let's explore all you need to know about gas cutting machines.

1. Introduction to Gas Cutting Machines

Gas cutting machines, also known as oxy-fuel cutting machines, utilize a combination of oxygen and a fuel gas, such as acetylene, propane, or natural gas, to generate a high-temperature flame for cutting metal. These machines are capable of cutting through various metals, including carbon steel, stainless steel, aluminum, and other alloys, with precision and speed.

2. Operating Principles

Gas cutting machines operate based on the principle of combustion. The fuel gas is mixed with oxygen and ignited to create a high-temperature flame, typically exceeding 3,000 degrees Celsius (5,400 degrees Fahrenheit). The intense heat generated by the flame melts the metal surface, while the oxygen stream blows away the molten material, resulting in a clean and precise cut.

Gas Cutting Machine

3. Components of Gas Cutting Machines

Gas cutting machines consist of several key components, including:

Gas Cylinders: Containers filled with oxygen and fuel gas, connected to the cutting torch via hoses.

Cutting Torch: The handheld device that delivers the oxygen and fuel gas mixture to the workpiece and directs the cutting flame.

Regulators: Devices used to control and regulate the flow of oxygen and fuel gas from the cylinders to the cutting torch.

Gas Hoses: Flexible hoses that connect the gas cylinders to the cutting torch, allowing for mobility and flexibility during operation.

Cutting Tips: Replaceable tips attached to the cutting torch, designed to produce different flame sizes and cutting speeds based on the material thickness and type.

Ignition System: Mechanism for igniting the oxygen-fuel mixture to initiate the cutting process.

4. Safety Considerations

Operating gas cutting machines requires strict adherence to safety protocols to prevent accidents and injuries. Some essential safety considerations include:

Proper Ventilation: Ensure adequate ventilation in the work area to prevent the accumulation of flammable gases and fumes.

Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, face shields, flame-resistant clothing, and gloves, to protect against heat, sparks, and molten metal.

Secure Gas Cylinders: Properly secure gas cylinders in an upright position and use protective caps to prevent damage and leaks.

Check for Leaks: Inspect gas hoses, connections, and regulators for leaks before use, and test for leaks using a soapy water solution.

Fire Safety: Have fire extinguishing equipment readily available in case of emergencies, and follow proper fire safety procedures.

5. Applications of Gas Cutting Machines

Gas cutting machines are used in various industries and applications, including:

Metal Fabrication: Cutting metal sheets, plates, pipes, and structural components for fabrication and manufacturing processes.

Construction: Cutting metal components for construction projects, such as beams, columns, and support structures.

Shipbuilding: Fabricating and assembling metal components for ship hulls, decks, and superstructures.

Automotive: Cutting metal parts and panels for automotive repair, restoration, and customization.

Demolition: Dismantling and cutting metal structures and equipment in demolition and salvage operations.

Gas cutting machines offer a versatile and efficient solution for cutting metal materials in various industries and applications. By understanding the operating principles, safety considerations, and applications of gas cutting machines, operators can achieve precise and high-quality cuts while ensuring safety and compliance with industry standards.