Cutting torches are essential tools used in various metalworking and fabrication processes to efficiently and precisely cut through metals. Whether you're a professional welder or a DIY enthusiast, choosing the right cutting torch is crucial for achieving accurate and clean cuts. This guide provides valuable insights into the factors to consider when buying cutting torches, helping you make an informed decision that meets your cutting needs.

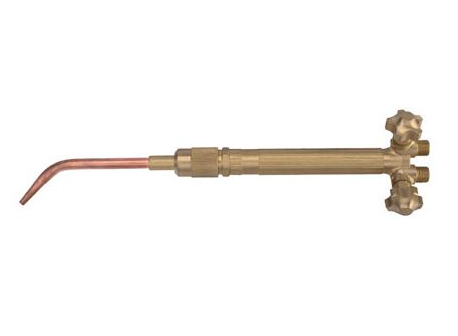

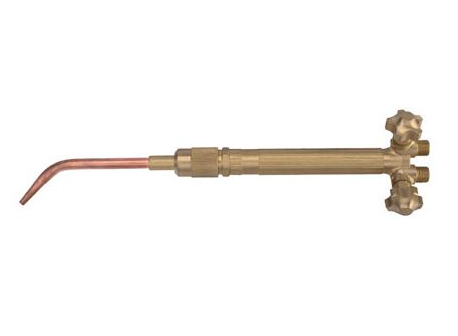

Cutting Torch

Types of Cutting Torches

There are several types of cutting torches available, each designed for specific applications:

Cutting Torch

Factors to Consider

When purchasing a cutting torch, consider the following factors to ensure it meets your cutting requirements:

Type of Fuel: Choose a torch that is compatible with the type of fuel you plan to use, whether it's acetylene, propane, or other gases.

Cutting Torch

Benefits of Using Cutting Torches

Choosing the right cutting torch can offer several benefits:

Conclusion

Investing in a suitable cutting torch is essential for achieving accurate and efficient metal cutting results. By considering factors such as application, type of fuel, cutting capacity, and ease of use, you can select a cutting torch that meets your specific needs. Whether you're working on large-scale industrial projects or intricate artistic designs, a well-chosen cutting torch will be a valuable tool in your metalworking arsenal.