One of the first things I learned as a beginner is that whatever you are welding, it must be well grounded, or your welds, consumables, and everything else will be compromised.

So how do you ground your welder? Welders are usually earthed using a grounding clip, usually made of copper or brass. This is done to complete the circuit and allow the welder to create an arc. Without good grounding, it can affect the quality of the weld and consumables, or even stop you from welding.

It is vital that the welder is earthed before you start work. If you are unsure why you need to ground your welder, read on.

Welder Grounding Safety Tips You Should Never Ignore

Proper grounding isn't just about welding quality—it's about personal safety. One of the biggest risks when welding without a solid ground is electric shock, especially in damp or poorly ventilated environments. Always inspect your cables and clamps for wear or corrosion, and never attach the clamp to painted or rusted surfaces. Before beginning any job, verify that all connections are tight and your ground lead is securely clamped. These small precautions can prevent equipment damage and ensure you return home safely after each project.

Why do you ground a welder?

Grounding the electrical circuit is a very common safety practice and this is the main reason for grounding the welder. Maintaining proper grounding in an arc welding setup is essential for safety in the workspace. Another reason for earthing is to improve the quality of the weld. All your welding current will pass through the fixture.

This means that if you have a poor connection, the performance of the welder will be compromised, resulting in a lower-quality weld.

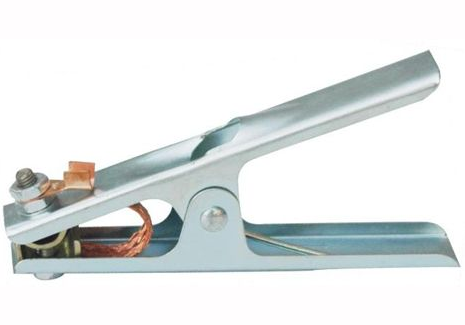

Earth Clamp HBEC-511

How do I ground the welder?

Grounding the welding machine is as simple as placing the ground clamp on the workpiece. It is always a good idea to ground the clamp to clean the metal and as close to the welding position as possible.

Inside most clamps, there is a grounding strap connected to the lug. Once that contact plate burns out, the clamp will not be as effective and you will need to replace your clamp. Some of the larger clamps are made entirely of conductive material with spring-loaded jaws to aid connection.

Best Ground Clamps for Beginner Welders

If you're just starting with welding, choosing the right ground clamp can be confusing. For hobbyists or entry-level users, spring-loaded copper clamps are an excellent choice due to their ease of use and reliable conductivity. Look for clamps with a firm grip, high-amperage capacity (at least 300A), and solid build materials like copper or brass. Avoid plastic-coated or lightweight models, as they may not maintain a consistent connection under real working conditions. Investing in a durable, beginner-friendly clamp will help you achieve better results and build good habits from day one.

If you are lucky enough to be working on a metal bench, you can fix the floor directly to the bench where it is clean and out of the way. Make sure you don't lean on the clamp while welding or you could get an electric shock!

Welding Machines

Where to place the earthing clamps when welding?

One of the important things to know is where to place the earth clamp when welding. The earthing clamp (grounding clip) needs to be attached to the substrate you are welding. It also needs to be close to the area where you are welding. In fact, you can even clamp it directly onto the plate where the workpiece is located; just make sure you don't clamp it to anything leaning against the wall.

A metal workbench or table is also a good place to put the clamp. If your work doesn't touch that metal table, again ...... can simply clamp it to your workpiece. The closer to the area you are working in, the better.

You also need to make sure that your mounting clamps are on clean metal. If you don't have the metal ready, it will be a very poor connection. Make sure it is free from rust and paint. Without this extra protection, you may be shocked and the quality of your weld may be poor.

Common Grounding Problems When Welding on Painted Metal

Painted or coated metal surfaces can significantly reduce the effectiveness of your ground connection. Since paint acts as an insulator, it prevents full electrical conductivity between the ground clamp and the base material. To solve this, always grind off a small clean patch of bare metal before attaching your ground. This is especially important when working with automotive panels, galvanized steel, or powder-coated parts. Neglecting this step can cause arc instability, poor penetration, or even equipment malfunction.

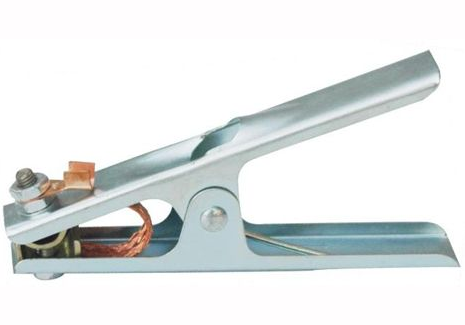

Earth Clamp HBEC-514

Extra care needs to be taken when soldering automotive items. You must not clip the earth wire to the heel.

If you do so, you could damage the wheel bearings. Newer cars also tend to run on power at all times, even if they are left idle without the key or ignition. For added safety, you can loosen the battery before welding or disconnecting the alternator.

In any case, MIG welding is usually very safe. You just need to make sure that you don't let the battery leads touch the bodywork when you disconnect them.

How to Test If Your Welding Ground Clamp Is Working Properly

A faulty ground clamp can cause weak arcs, excessive spatter, and poor weld penetration. To test your ground clamp, use a multimeter to measure the resistance between the clamp and the workpiece. Ideally, the reading should be close to zero—anything above 0.1 ohms might indicate poor conductivity. Also, check for visible signs of wear on the contact points and internal strap. If you suspect damage, replace the clamp immediately to avoid welding performance issues or safety risks.

High-quality ground clamps will improve the quality of your welding and make it more enjoyable. The fewer things that go wrong, the more you can focus on setting up your welder correctly. Not only that, but a well-grounded welder will ensure that you are as safe as possible.

Earth Clamp HBEC-514D

The beauty of grounding clamps is that once you know how they work, they are very easy to use. Always make sure you have a clean piece of material to clamp onto. If you are using old or repainted material, you should also clean a small area of your project to ensure you get the best ground possible.

Once you have mastered the art of grounding and working leads, you will be better able to lay down some quality welds and, most importantly, you will be able to do so in a safer manner. Always read the manual on your welder carefully before using it as it may be different from what you are used to and it is always worth being safe rather than sorry when electricity is involved.

Tips to Improve Welding Current Flow with Better Grounding

Stable current flow is essential for achieving consistent, high-quality welds. One often overlooked factor is the condition and position of the ground clamp. Keep the cable as short as possible to reduce voltage drop, and place the clamp close to the welding point to minimize resistance. Use thick-gauge cables for high-amperage jobs, and regularly clean the clamp's contact area. Even small resistance can cause arc fluctuation or overheating. By optimizing your grounding setup, you can ensure smoother current flow, cleaner weld beads, and less strain on your equipment.

If you have any tips on grounding your welder or would like to recommend a brand of grounding clamp to other welders, please do not hesitate to contact Hebei Machinery directly.

It is our great honor to satisfy your requirements for welding products. Any requirement from you will be maximized by us.

Need expert advice or looking to buy high-quality welding clamps? We're here to help.

Contact Us Today