The installation, operation, and maintenance of arc welding equipment and the use of the procedures described in this document should only be carried out by qualified personnel in accordance with the applicable codes, safety practices, and the manufacturer's instructions.

Always ensure that the work area is clean and safe and that proper ventilation is used. Incorrect use of equipment and failure to comply with applicable codes and safety practices may result in serious personal injury and property damage.

Introduction

Oxygen/acetylene welding or "gas welding" is a process that relies on the combustion of oxygen and acetylene. When mixed together in the correct proportion in a hand-held torch or blowpipe, a hot flame with a temperature of approximately 3,200° is produced. The chemical action of the oxygen/acetylene flame can be adjusted by changing the volume ratio of oxygen to acetylene, using a valve on the torch or blowpipe.

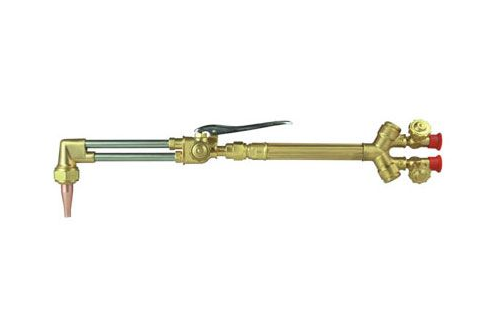

Gouging Torch

Equipment

The oxygen/acetylene equipment is portable and easy to use. It contains oxygen and acetylene gas stored under pressure in cylinders. The cylinder should be fitted with a regulator to control the pressure and flow of the gas. A flexible hose is used to connect the regulator to the torch or blowpipe. Between the hose and the regulator a specially designed safety device called a flame arrestor or "flashback arrester" is fitted. The flashback flame arrestor prevents the flame from the "flashback" from reaching the cylinder.

Flashback

Flashback is a rapid, high-pressure return of flame to a gas hose, caused by incorrect pressure settings under welding or cutting, or by clogged or overheated nozzles (for example, nozzles operating too close to the material).

Flashback can lead to extremely dangerous cylinder ignition and must be prevented by the correct use of a working flashback arrester.

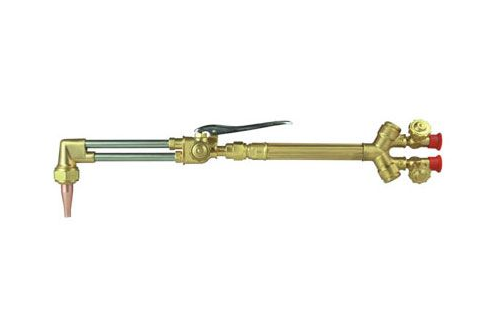

Welding Torch

Lighting procedures

To begin oxygen/acetylene welding or cutting, it's important to follow the proper lighting procedure to ensure safety and efficiency. Start by opening the cylinder valve of the oxygen/acetylene unit slowly using a cylinder key. Do not open the valve suddenly to avoid potential damage to the regulator or cause accidents. Open the cylinder valve spindle only one turn to allow for a controlled release of gas.

Next, open the gas control valve on the blowpipe and adjust the regulator to provide the correct working pressure. This step ensures that any air or oxygen is purged from the hose before ignition. Repeat the process on the oxygen side to ensure both gases are properly prepared.

Igniting the Torch:

Use a suitable welding torch to ignite the gas, ensuring that the torch is held at a right angle to the nozzle. Never use a liquid igniter (e.g., cigarette lighter) as the vapor/gas combination could be hazardous.

Once the gas is ignited, adjust the acetylene supply through the blowpipe valve until the flame stops smoking. Then, slowly increase the oxygen supply through the blowpipe control valve until the white inner cone of the flame is clearly visible with just the slightest haze of acetylene. This indicates that the blowpipe is properly adjusted for optimal welding or cutting.

About Us: Hebei Machinery Manufacturing

With over 20 years of experience in manufacturing and exporting welding machinery, welding consumables, and welding components, Hebei Machinery Manufactory is a trusted leader in the industry. Our products include:

Welding Electrodes Production Line

Welding Machines

Plasma Welding Machines

Cutting Machines

Welding Torches & Cutting Torches

Welding Wires

Welding Electrodes

And other related welding products

We take great pride in providing high-quality products that meet your specific welding needs. No matter your requirements, we are committed to delivering solutions that exceed expectations.

Request a Quote or More Information

Interested in learning more about oxy-acetylene welding techniques or our range of welding products? Feel free to contact us today for further information or to request a quote. We are dedicated to meeting all of your welding needs and ensuring the highest levels of satisfaction.