In order to fully establish the differences between MIG and stick welding, we will compare some of their key parameters:

1. Weld quality

MIG welding tends to have a better aesthetic quality than stick welding because stick welding produces spatter and slag. However, in contrast, when welding thicker metals with MIG, the current intensity needs to be cranked up and the surface needs to be completely free of paint and corrosion to avoid affecting the depth of the weld. If done correctly, stick welding will produce a much stronger joint than MIG welding. 2.

2. Indoor and outdoor applications

As MIG welding involves the use of shielding gas, it should only be carried out indoors, as wind or rain can affect the weld. Stick welding, on the other hand, is wind and water resistant and can therefore be carried out outdoors or even underwater. However, arc stick welding produces a lot of fume and smoke, which means that good ventilation is required for the safety of the welder.

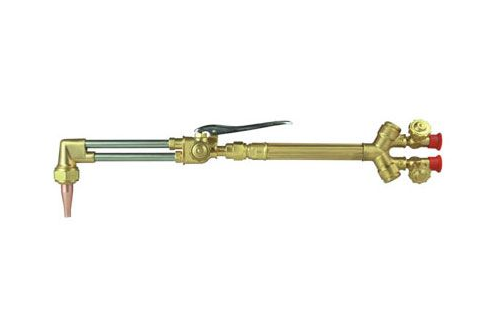

Welding Torch

3. Metal type and thickness

MIG welding can be carried out on different types of metal as long as the surface is clean, MIG welds can be used on thin metals including aluminium, brass, carbon steel, copper, magnesium, mild steel and stainless steel. However, MIG welding is not suitable for thicker metals and does not melt thicker metals as well as stick welding. In contrast, stick welding is not as effective on thinner metals as it can lead to burn through.

4. Applications

MIG is a clean and fast process that is suitable for a range of applications from small DIY projects to large industrial welding tasks. However, MIG is not suitable for outdoor or more extreme conditions and for welding thicker materials. Stick welding is preferred in these situations.

5. Ease of use

Although stick welding is not a particularly difficult skill to learn, MIG welding is a much easier technique to master, allowing you to operate one component at a time, press a trigger to automatically wind the wire and start welding. Stick welding is slightly more difficult as you need to draw the arc accurately without damaging the weld metal.

6. Portability

Stick welding equipment is more portable than MIG welders because it does not require an external shielding gas source.

7. Cost

MIG welding equipment is more expensive than a stick welder, although when carried out on an industrial scale, MIG welding becomes more cost effective due to factors such as increased productivity.

Read More: Difference Between MIG and TIG Welding.