Guide to Choosing TIG Wire HoldersTungsten Inert Gas (TIG) welding demands precision and control, and the choice of TIG wire holders plays a crucial role in achieving optimal welding results. Whether you are a seasoned welder or a beginner, this guide will help you navigate the factors to consider when selecting the right TIG wire holder for your welding projects.

Compatibility and Size

Begin your selection process by ensuring compatibility with your TIG welding machine. Check the specifications of the TIG wire holder to ensure it fits securely with your equipment. Additionally, consider the size of the holder, as it should accommodate the diameter of the TIG wire you intend to use. A secure fit ensures stability during welding, contributing to better control and accuracy.

Material and Build Quality

Assess the material and build quality of the TIG wire holder. High-quality materials, such as durable metals or alloys, contribute to longevity and reliable performance. A well-constructed holder can withstand the rigors of TIG welding, including heat and potential impacts. Look for holders with robust construction to ensure they can withstand the demands of your welding projects.

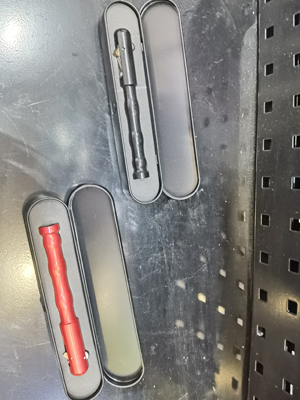

TIG Wire Holders

Ergonomics and Comfort

Comfort is key during long welding sessions. Evaluate the ergonomics of the TIG wire holder, considering factors such as grip design and weight. An ergonomic holder reduces fatigue, providing better control and precision during welding. Look for features like insulated handles that offer a comfortable grip and minimize heat transfer to your hands.

Heat Resistance and Insulation

TIG welding involves high temperatures, so it's essential to choose a wire holder with excellent heat resistance. Insulation features, such as heat-resistant coatings or materials, prevent overheating and ensure the longevity of the holder. Consider holders with effective insulation to protect both the equipment and the welder from excessive heat exposure.

Adjustability and Versatility

Opt for TIG wire holders that offer adjustability to accommodate various welding angles and positions. Versatility in adjustment ensures flexibility in your welding projects, allowing you to achieve precise welds in different scenarios. Look for holders with swiveling or adjustable features that enhance your ability to weld in challenging positions.

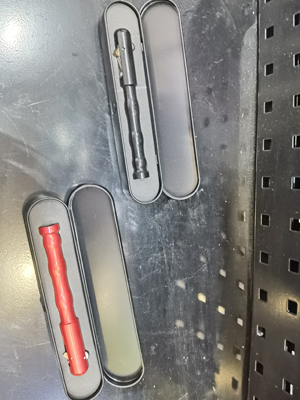

TIG Wire Holders

Cost and Brand Reputation

While cost is a consideration, prioritize the overall value of the TIG wire holder. Invest in a reputable brand known for producing reliable welding accessories. Quality often comes with a higher price tag, but the durability and performance of a well-known brand can outweigh the initial cost. Read reviews and testimonials to gauge the reputation of the brand and make an informed decision.

Frequently Asked Questions

Q: Why is the size of the TIG wire holder important?

A: The size of the TIG wire holder ensures a secure fit with the welding machine and accommodates the diameter of the TIG wire, contributing to stability and control during welding.

Q: How does the ergonomics of the TIG wire holder impact welding?

A: Ergonomic design reduces fatigue during welding, providing a comfortable grip and better control for precise and accurate welds, especially during long sessions.

Q: Why is brand reputation important when choosing a TIG wire holder?

A: A reputable brand is likely to produce high-quality and durable TIG wire holders, ensuring reliability and performance in your welding projects.

In conclusion, choosing the right TIG wire holder involves considering compatibility, material quality, ergonomics, heat resistance, adjustability, and brand reputation. By paying attention to these factors, you can select a TIG wire holder that enhances your welding experience and contributes to the success of your projects.

For more information, please contact us. We will provide professional answers.