Selecting the right size welding torch is crucial for achieving the best results in your welding projects. The size of the welding torch depends on several factors, including the type of welding you'll be doing, the thickness of the materials you're working with, and your comfort and control preferences. Here's how to determine the size of welding torch you need:

Welding Process:

The first consideration is the type of welding process you'll be using. There are various welding processes, such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick (Shielded Metal Arc Welding), each of which may require a different torch size. Ensure that the torch you choose is compatible with the welding process you plan to use.

Material Thickness:

The thickness of the materials you'll be welding is a critical factor in selecting the right torch size. Thicker materials generally require more heat and a larger torch. As a general guideline:

For MIG welding, a 150-amp torch is suitable for welding materials up to 1/4 inch thick, while a 200-amp torch is recommended for thicker materials.

For TIG welding, a torch with a lower amperage rating can be used for thinner materials, while a higher amperage torch is needed for thicker materials.

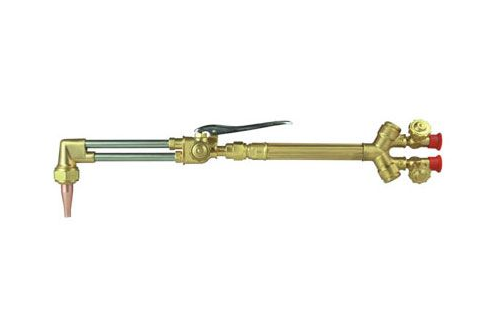

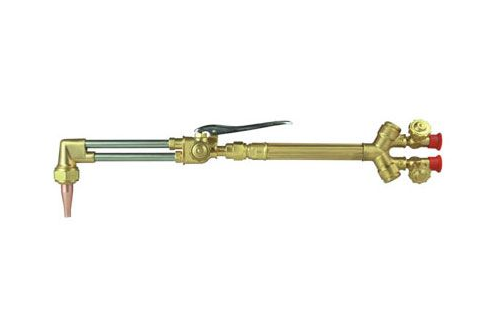

Welding Torch

Amperage Rating:

Amperage is an essential factor when choosing a welding torch. The amperage rating of the torch should match or slightly exceed the amperage output of your welding machine. Selecting a torch with the correct amperage rating ensures that it can handle the current required for your specific welding application.

Comfort and Control:

Consider your comfort and control preferences when selecting a welding torch size. A larger torch may offer better control and handling for some welders, especially when working on long or continuous welds. However, for finer and more detailed work, a smaller torch may provide greater precision and ease of maneuverability.

Duty Cycle:

The duty cycle of your welding machine also plays a role in choosing the right torch size. The duty cycle indicates how long you can weld continuously before the machine needs to cool down. A larger torch, which may require more current, could result in a shorter duty cycle. Ensure that your welding machine and torch combination can handle the workload without overheating.

Personal Preferences:

Ultimately, your personal preferences and welding style can influence the size of the torch you choose. Some welders prefer larger torches for the added stability and control, while others may opt for smaller torches for their lightweight and ease of maneuverability. It's essential to find a torch size that suits your welding technique and feels comfortable in your hands.

Consult with a Welding Professional:

If you're unsure about the appropriate torch size for your specific welding project, don't hesitate to seek advice from a welding professional or the manufacturer of your welding machine. They can provide recommendations based on your needs and the type of welding you'll be performing.

In summary, selecting the right size welding torch involves considering factors like the welding process, material thickness, amperage rating, comfort and control preferences, duty cycle, and personal preferences. It's important to strike a balance between these factors to ensure that your welding torch suits your application and provides the best results. If you're uncertain, consult with a welding expert or manufacturer to get tailored guidance.